The announcement is impressive. The CEO celebrates it publicly. The dashboards show perfect metrics. Compliance case processing time: down 75%. Throughput: up 400%. User satisfaction: trending positive.

Leadership frames it as "the largest leap in operational effectiveness we've ever achieved." It's positioned as evidence of strategic execution, proof that the organization is becoming faster, leaner, more capable.

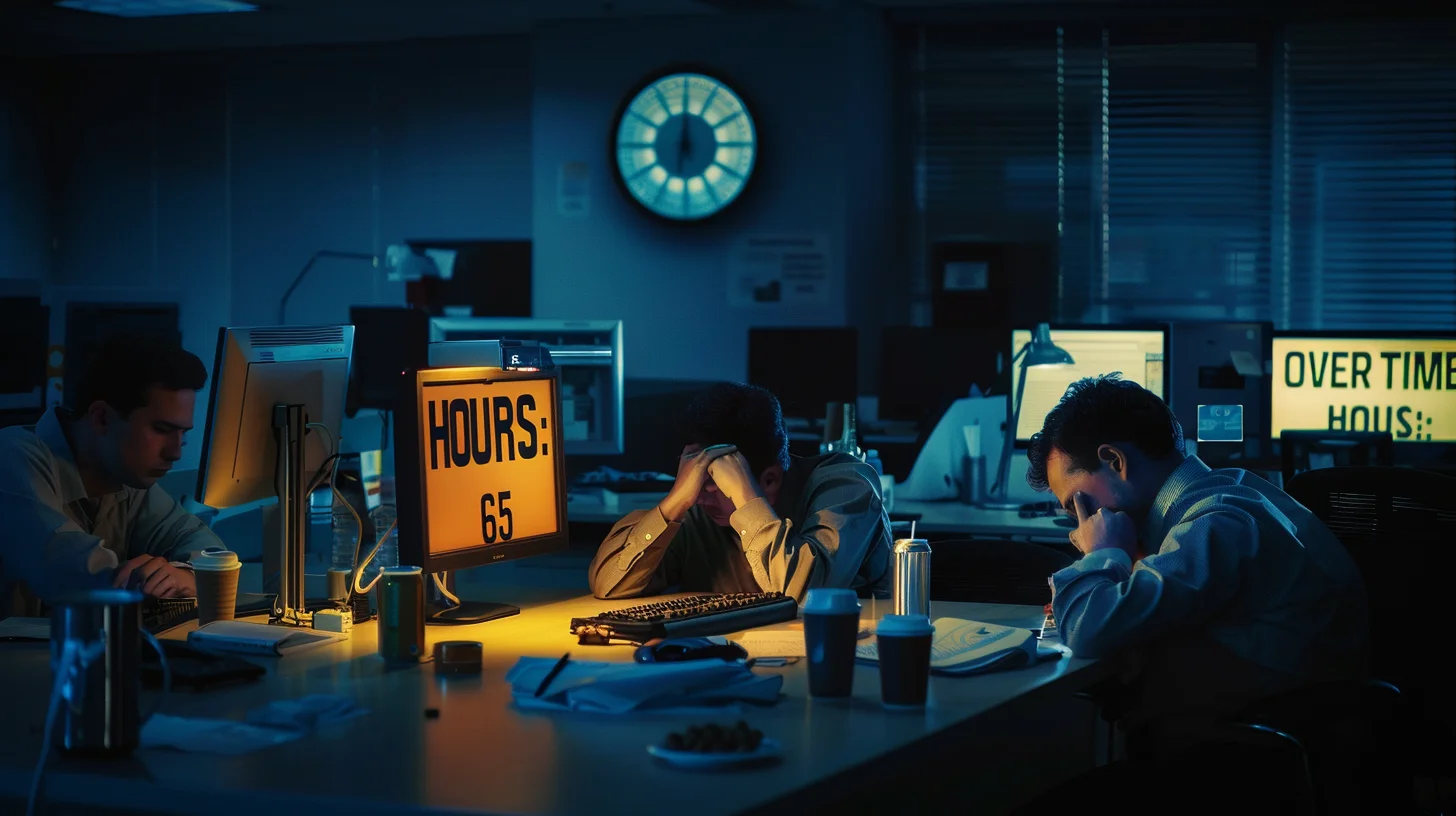

But here's what the metrics don't show: the compliance team is working nights and weekends. The process architecture hasn't changed. The tooling is the same. The 4× improvement didn't come from system optimization — it came from system compression

The speed increase is real. But it's not sustainable. It's not scalable. And it's not a sign of organizational maturity. It's efficiency theatre — performance metrics that mask structural degradation.

This is what happens when narrative overtakes reality. When dashboards become the product, not evidence of the product. When leadership celebrates outcomes without investigating mechanisms.

Anatomy of Efficiency Theatre

The mechanics are consistent. These aren't isolated incidents — they're predictable patterns in organizations that prioritize optics over operations.

Dashboard: ✅ Green across all metrics

Celebration: "Largest efficiency jump in history"

At the surface level, everything looks like strategic excellence. The company demonstrates "focus on measurable results." The team appears heroic. Leadership looks decisive. But if you remove the dashboard layer, what's underneath is compression, not capability.

Tooling: Same systems

Quality criteria: Unmodified

Actual change: Team working 60+ hour weeks

The gain isn't from process redesign or improved tooling. It's from intensification — overtime, priority shifts, elimination of recovery buffers. Short-term: productivity spike. Long-term: error rates climb, resilience collapses, trust erodes. The system didn't become more efficient. People became more exhausted.

• Continuous overtime (no boundary enforcement)

• Task prioritization at expense of other work

• Elimination of slack/buffer time

• No process optimization or tooling improvement

This pattern delivers short-term metric improvements by borrowing from future capacity. It's credit against stability. Organizations celebrating these "wins" risk entering a phase where narrative replaces reality, and metrics become cover for systematic degradation rather than evidence of health.

• Team burnout trajectory

• Error rate trends (delayed 2-3 months)

• Knowledge transfer gaps from rushed work

• Attrition risk accumulation

True performance is quiet — it sustains itself without applause. Sustainable efficiency grows with controllability, scalability, and quality. Any speed gain without these components is borrowed time. The question isn't whether the team can deliver — it's whether they can keep delivering.

The pattern: when a company starts celebrating heroic efforts instead of systematic improvements, you're watching a system learn to mistake resource extraction for operational maturity

The Core Symptom

In healthy systems, speed comes from removing friction. In theatre, speed comes from adding pressure

The diagnostic is straightforward: growth without system change is compression, not improvement.

Watch for these markers: Metrics improving while team capacity degrades. Leadership celebrating outputs without examining sustainability. Public narratives about "operational excellence" paired with invisible overtime. And most critically — no one asking what happens when the team stops absorbing the load.

This isn't about occasional crunch periods or short-term pushes. Those are normal. This is about systematically misidentifying resource extraction as capability building, then institutionalizing it through celebration and repetition.

The Diagnostic Questions

Before celebrating efficiency gains, you need to know if they're real or theatrical. These questions reveal whether you're looking at capability growth or capacity compression.

Reality Check Questions

Ask about mechanism:

"What specific process changes or tooling improvements enabled this speed increase?"

→ If the answer is vague or focuses on "team dedication," you're watching compression, not optimization

Ask about sustainability:

"Can we maintain this throughput with the same team for another 6 months? 12 months?"

→ If there's hesitation or qualification, the efficiency gain is borrowed time, not structural improvement

Ask about capacity:

"What's the team's actual working hours compared to three months ago?"

→ If hours increased proportionally to output, you haven't gained efficiency — you've increased load

Ask about quality:

"What's the error rate trend? What's the rework percentage?"

→ If quality metrics lag by 2-3 months, you won't see the degradation until the damage is systemic

The distinction: Real efficiency scales without additional human cost. Theatre efficiency requires constant human sacrifice to maintain the illusion

If you're the one leading the system: differentiate between building capability and extracting capacity. Ask whether your "wins" come from system improvements or system stress. If your speed gains disappear when people work normal hours, you're not operationally excellent — you're operationally fragile.

it doesn't need applause, it sustains itself